What is Hazard and Operability Analysis?

HAZOP is an abbreviation of Hazard and Operability. It is the most widely used method for the identification of hazards, especially in the chemical industry. .

HAZOP Study is a method defined by IEC 61882 standard. The IEC 61882 standard specifies the minimum requirements that must be applied during the execution of the HAZOP Study.

The selection of the tool used in the hazard identification and risk analysis studies performed during the Process Safety Management process is very important. Failure of the selected technique may lead to inability to create the right scenarios and to make wrong investment decisions. Within the CCPS-Center for Chemical Process Safety publications, the Guidelines for Hazard Evaluation Procedures has identified a guiding selection method for the selection of hazard detection tools.

How is Hazard and Operability Analysis (HAZOP) Applied?

Hazard and Operability Analysis (HAZOP Study) was developed to evaluate chemical production processes. However, it is used as an important hazard identification and risk assessment tool in many areas such as software development after it has proved its effectiveness and can be applied in many different industries.

Hazard and Operability Analysis (HAZOP Study) The most important plus of the study is that the results of the study systematically reveal hazards and operability problems. The characteristic feature of HAZOP studies is to create a multidisciplinary team with the help of a leader and analyze it in sessions.

HAZOP study is carried out with the binary variable method approach. When the systematic study is examined, it is necessary to determine a team suitable for the purpose of the study in the facility where HAZOP Study will be performed. After the creation of the team and the schedule determination, the plant parts to be evaluated in the HAZOP Study are divided into nodes (NODE). Node points (NODE) should be done carefully and in accordance with HAZOP standard and guiding publications in order to perform the HAZOP study correctly. Once the nodes have been identified, each node must be analyzed using the binary variable method.

Binary variable method is used to determine deviations from routine operation with parameter and auxiliary word. Some of the parameters used in HAZOP Study are given in the table below;

- Flow

- pH

- Corrosion

- Level

- Pressure

- Particle Size

- Temperature

- Composition

- Time

| Flow | pH | Particle Size |

| Temperature | Composition | Corrosion |

| Level | Time | Pressure |

The determined parameters are converted into deviations with the help of auxiliary words. We can make the “Level” parameter deviate by using the auxiliary word as follows;

All parameters determined for each node (NODE) are converted into deviations with the help of auxiliary words, and each deviation is analyzed by evaluating all root causes that may cause this deviation and all possible results.

Hazard and Operability Analysis Stages

Hazard and Operability Analysisis a very important tool in the risk analysis and risk management processes that are performed within the scope of process safety. With the HAZOP Study, we have the opportunity to qualitatively analyze the adequacy of scenarios and existing protection methods that are likely to have a process accident in our process. With HAZOP Study, we prepare infrastructure for determination of SIL requirement to be realized within the scope of functional safety (IEC 61511). . Scenarios that we believe that our existing measures are not sufficient as a result of HAZOP Study are transferred to numerical evaluation methods as Safety Instrumented Function (SIF). We can then determine the Safety Integrity Level (SIL) of the designated Safety Instrumented Function (SIF) and design our Safety Instrumented System (SIS).

Hazard and Operability Analysis is a kind of brainstorming work and is recommended to be performed by a multidisciplinary team. This situation can make the work as detailed as possible and also negatively affect the working time. At this point, it is recommended that the right people participate in sufficient number of HAZOP studies by HAZOP leaders. In addition, the following documents and information are needed for HAZOP studies to be effective and productive;

- Process Safety Information

- Piping and Instrumentation Diagram (P&ID)

- Process Flow Diagram

- A leader with experience in HAZOP studies and a clerk to provide documentation throughout the study

- Past accident reports

- HAZOP systematic and template documents determined in Process Safety Management System

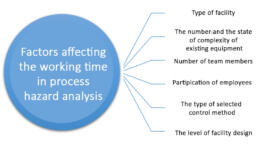

As in all Process Hazard Analysis, duration is the most important yield factor in hazard and Operability analysis. The correct determination of the working time at the beginning will positively affect the motivation of the team members in the working process. At this point, it is recommended to determine the time before the study.

Our Services

Our Trainings

Hazard and Operability Analysis (HAZOP)

Can existing process hazards be foreseeable? How effective is HAZOP analysis? Do I need a new security system?

Keywords: HAZOP, HAZOP Study, Hazard and Operability Analysis, HAZOP Staff, HAZOP Training, HAZOP Study Preparations, HAZOP Study Team, HAZOP Study Preparation

Takipte Kalın

Takipte Kalın