Meltem SÖĞÜTCEPINAR

Chemical Engineer

Human Factors and Human Error

According to Whittingham, human error is defined as “an undesirable failure of a purposeful action, either alone or as part of a planned series of actions, to achieve a specified outcome, both within the defined tolerance limits for the action itself and the outcome.”[1] As a result of increasing chemical facilities day by day, the number of work accidents due to human origin in the chemical industry is also increasing. When the root causes of accidents in the chemical industry are examined, it is understood that 65% of them are human-related accidents.

Figure 1. Root cause rates of accidents in the Chemical Industry

Human factors are used to identify and reduce the sources and consequences of human errors. The human factor is a discipline that considers human interaction with the rest of the system, such as the environment, facilities, equipment.

The three aspects that human factors consider are as follows.

- To ensure ergonomics in the working environment by matching the design and operating procedures of the equipment with the physical abilities of the operators.

- Matching equipment design and operating procedures with operators’ cognitive abilities and characteristics.

- Assessing how the organization’s safety culture and attitude affects the way processes are run.

The purpose of using human factors is to evaluate human performance in the current situation and to continue to protect process safety by determining and taking necessary actions. This is achieved by analyzing the capabilities and limits of those working in the facility and matching them to equipment and processes.

While most of the early studies were concerned with the physical abilities of the employee when analyzing the abilities and limits of an employee in a facility, today these analyzes focus on mental tasks as well as physical tasks. In this way, the task distribution in the facility is made in the most efficient way, and the tasks are automated.

Even though developing technology and modern control systems have a high degree of automation, people still have overall responsibility for the safe and economical operation of the plant. For this reason, in order for humans to be able to provide this capability, systems that protect and tolerate human errors and trainings are required to improve the decision making of operators in these abnormal situations.

Human errors occur in the ergonomics, cognitive factors, and safety culture deficiencies that the human factor takes into account. At this point, human errors arising from two main sources are related to engineering. The first of these is the accident investigation, and the second is the hazard assessment, in which the interaction between human and system performance can be evaluated. When human error root cause accidents are examined, the obvious predominance of human errors is noticed. The main causes of human errors are given in Figure 2.

.

Şekil 2. İnsan Hatalarının Nedenleri [2]

İnsan hatasına sistematik bir yaklaşımda hatalar sınıflandırılmış olmalı ve doğrudan veya dolaylı şekilde uygun modellere dayandırılmalıdır. Sınıflandırmanın tek boyutta olması gerekmemektedir. Tesiste çalışanların çoğu sınıflandırmayı iki boyutlu olarak yürütmektedir.

- İnsan davranışı

- Görev özellikleri

İnsan hatası sınıflandırmasında günümüzde değerlendirme içine alınan bilişsel faktör ise bir diğer önemli konudur. Rasmussen[3] proses kontrolü gibi bir görevi yerine getirmek için 3 insan yaklaşımı tipi veya seviyesi ayırt etmektedir. Bu tip veya seviyeler aşağıdaki gibidir.

- Beceri bazlı

- Kural bazlı

- Bilgi bazlı

Operatör davranışının Rasmussen tarafından tanımlanması, genellikle Beceri-Kural-Bilgi (SRK) Modeli olarak adlandırılmaktadır. Beceri bazlı davranışlar veriye dayalı yeni bilgi kullanmadan yapılan otonom davranışlardır. Kural bazlı davranışlar ise bilinçli olarak kontrol edilmekte ve hedeflenmektedir. Bilgi bazlı davranışlar ise bilinçlidir ve akıl yürütmeyi içermektedir. Literatürde SRK modeli dışında talep-kapasite uyumsuzluğu modeli, tolerans değişkenliği modeli, zaman kullanılabilirliği modeli, beceriler-kurallar modeli, devamsızlık modeli, örgütsel model, ihllaller gibi farklı insan hata modelleri mevcuttur.

İnsan Hatası Değerlendirilmesinde İnsan Faktörü

İnsan hatası analizinde değerlendirme yaklaşımı, becerinin niteliği, öğrenme sürecindeki etkinliği ve stres altında öğrendiğini entegre edebilme başlıklarını dikkate alarak mevcut yeteneği araştırma eğilimindedir.

İnsan hatasının kantitatif değerlendirmesi için açıklanan yöntemler, öncelikle insan hatasıyla ilgili veri talebine ihtiyaç duymaktadır. İnsan hatası ile ilgili veriler birkaç yöntem ile elde edilebilmektedir. Bu yöntemler aşağıda listelenmiştir.

- Dokümantasyondaki görev analizi

- Doğrudan gözlemleme

- Sorgulama

- Uzmanlardan gelen bilgilerden sonuç çıkarma

CCPS ayrıca insan hata verisi toplama ve veri toplama sistemleri üzerinde de çalışmaktadır. Ve CCPS kılavuzunda bazı data toplama sistemleri,

- Olay Raporlama ve Araştırma Sistemi (IRIS)

- Kök Neden Analiz Sistemi (RCAS)

- Ramak Kala Olay Raporlama Sistemi (NMRS)

- Kantitatif İnsan Güvenilirliği Veri Toplama Sistemi (QHRDCS).

İnsan hatası modellerinin ve sınıflandırmalarının çoğunun uygulandığı genel çerçeve, görev analizi ile ilgilidir. Görevler, planlar ve eylemler gibi unsurlara ayrıştırılır ve bunlarla ilgili hatalar modellenmekte ve sınıflandırılmaktadır. Belirli modellerin uygulandığı genel bir çerçeve olmasının yanı sıra, görev analizi, özellikle hiyerarşik görev analizi, kendi başına bir model olarak kabul edilebilmektedir. İnsan hatasının yaygın bir sınıflandırması, eylemler açısındandır. Bu tip bir sınıflandırma, ihmal, görevlendirme, aksiyon almadaki gecikmeler vb. anlamına gelmektedir.

Görev Analizi aynı zamanda insan hatası değerlendirmelerinde kullanılan bir yaklaşımdır. Görev analizi, çeşitli amaçlar için geliştirilmiş farklı metodolojiler kullanan bir tekniktir. Örneğin, görev analizi; bilgi gereksinimlerinin belirlenmesinde, işletme prosedürlerini yazmada, eğitim ihtiyaçlarını belirlemede, göreve atama seviyelerini belirlemede, olasılıklı güvenlik değerlendirilmesindeki insan güvenirliğini hesaplamada ve problemleri araştırmada yardımcı olmaktadır.

Kantitatif İnsan Güvenilirliği Analizi (HRA)

Kantitatif Risk Analizi (QRA) kapsamında insan hatasının değerlendirilmesi çoğunlukla Bow-Tie analizi kısmında ele alınmaktadır, ancak insan aksiyonu aynı zamanda olay ağacında, bariyerlere veya korucuyu önlemlerde görülebilmektedir. İnsan faaliyeti görevlere göre parçalara ayrılabilir hatta görevin elementlerine göre de ayrılabilir. Bu parçalanmış unsurların her birine ayrı ayrı hata oranı atanabilmektedir. İnsanın bir parçası olduğu genel sistemin güvenilirliği, çeşitli bileşenlerin güvenilirliğinin doğrusal bir kombinasyonu ile bulunabilmektedir.

Proses Risk Değerlendirmesi içerisinde insan hatasına ilk sistematik yaklaşım Swain ve iş arkadaşları tarafından geliştirilen İnsan Hata Oranı Tahmin Tekniği (THERP) tekniğidir. Three Mile’daki kaza sonucu insan güvenilirliği analizi çalışmaları hızlandırıldı ve Nükleer Enerji Santrali Uygulamalarına odaklanan İnsan Güvenirlik Analizi El Kitabı (HRA Handbook), Nihai Rapor yayımlandı. El kitabında kullanılan genel yaklaşım Şekil 3’te gösterilmektedir.

Figure 2. Causes of Human Error [2]

In a systematic approach to human error, errors should be classified and directly or indirectly based on appropriate models. The classification need not be one-dimensional. Most of the employees at the facility carry out the classification in two dimensions.

- Human behavior

- Task speciality

The cognitive factor, which is included in the evaluation in human error classification, is another important issue. Rasmussen [3] distinguishes 3 types or levels of human approach to performing a task such as process control. These types or levels are as follows.

- Skill based,

- Rule based,

- Knowledge based.

The description of operator behavior by Rasmussen is often referred to as the Skill-Rule- Knowledge (SRK) Model. Skill-based behaviors are autonomous behaviors without using new knowledge based on data. Rule-based behaviors are consciously controlled and targeted. Knowledge-based behaviors are conscious and involve reasoning. In the literature, apart from the SRK model, there are different human error models such as demand-capacity mismatch model, tolerance variability model, time availability model, skills-rules model, absenteeism model, organizational model, violations.

The Human Factor in the Assessment of Human Error

Evaluation approach in human error analysis tends to search for existing talent, considering the quality of the skill, the effectiveness in the learning process, and the ability to integrate learning under stress.

The methods described for the quantitative assessment of human error primarily require a request for data on human error. Data on human error can be obtained by several methods. These methods are listed below.

- Task analysis in documentation

- Direct observation

- Inquiry

- Drawing conclusions from information from experts

CCPS also works on human error data collection and data collection systems. And some data collection systems in the CCPS manual,

- Incident Reporting and Investigation System (IRIS)

- Root Cause Analysis System (RCAS)

- Near Miss Reporting System (NMRS)

- Quantitative Human Reliability Data Collection System (QHRDCS).

The general framework in which most human error models and classifications are applied relates to task analysis. Tasks are decomposed into elements such as plans and actions, and related errors are modeled and classified. Besides being a general framework in which specific models are applied, task analysis, especially hierarchical task analysis, can be considered a model in its own right. A common classification of human error is in terms of actions. This type of classification may result in negligence, assignment, delays in acting, etc. means.

Task Analysis is also an approach used in human error assessments. Task analysis is a technique that uses different methodologies developed for various purposes. For example, task analysis; It assists in identifying information needs, writing operating procedures, identifying training needs, determining assignment levels, calculating human reliability in probabilistic security assessments, and investigating problems.

Quantitative Human Reliability Analysis (HRA)

Evaluation of human error in Quantitative Risk Analysis (QRA) is mostly covered in Bow- Tie analysis, but human action can also be seen in event tree, barriers or guard measures. Human activity can be segmented according to tasks or even according to the elements of the task. Each of these fragmented elements can be assigned a separate error rate. The reliability of the overall system of which the human is a part can be found by a linear combination of the reliability of the various components.

The first systematic approach to human error within Process Risk Assessment is the Human Error Rate Estimation Technique (THERP) technique developed by Swain and colleagues. Accidental human safety analysis work at Three Mile was accelerated and the Handbook of Human Reliability Analysis with Emphasis on Nuclear Power Plant Applications, Final Report was published. The general approach used in the handbook is shown in Figure 3.

Figure 3. Human Reliability Analysis Methodology

Tasks to be performed are defined as part of the basic process risk analysis. The HRA, on the other hand, evaluates the reliability in the performance of these tasks. One of the quantitative Human Reliability analysis techniques is THERP and the starting point is a task analysis for each job to be done. This method is based on the original THERP technique and uses the aforementioned approach of breaking down tasks into small chunks. The basic assumption is that the task performed was planned.

There is an increasing trend to experimental work with operators on simulators to relate the probability of operators to failure over time.

In particular, Time Reliability Correlation (TRC) is used to obtain probabilities of human error in complex or non-routine processes, including the management of an emergency. The underlying assumption of such a TRC is that time dominates, although in principle there are other factors that affect operator performance on such tasks. A series of TRC models have been produced based on the simulator results. The task analysis approach on which THERP is based is not well adapted to keeping operators’ behavior in an anomalous state. For this, TRC approach is used.

Factors affecting operator performance other than time,

- External factors,

- Situational features

- The task and the characteristics of the equipment,

- Work and task procedures,

- Internal factors

- Stress sources

As all these factors were determined, new human reliability analysis methods were produced. The main human error analysis methods in the literature,

- THERP

- ASEP

- HEART

- TRC

- ATHEANA

- SLIM- MAUD

- TESEO

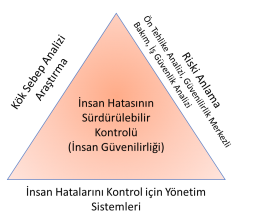

Human behaviors and performances are cited as the root cause of most of the accidents that occur in the process area. The human factor in the decision-making process, even involuntarily, is the main cause of events directly related to the use of the product. The human factor must be better understood, and the knowledge applied more broadly if the accident rate is to be reduced. Figure 4 shows the framework that needs to be installed in order to maintain human reliability.

Figure 4. Controlling Human Error [4]

Click here to review our other technical publications such as Human Factors and Human Error.

References

[1] The blame machine : why human error causes accidents / Robert B. Whittingham. Elsevier (2004)

[2] MHRA Annual Statistics, 2011

[3] Mannan, S., Lees’ Process Safety Essentials Hazard Identification, Assessment and Control

[4] Bridges, W., Tew, R., Human Factors Elements Missing from Process Safety Management (PSM), American Institute of Chemical Engineers 2010 Spring Meeting 6th Global Congress on Process Safety and the 44th Annual Loss Prevention Symposium, San Antonio, Texas, 2010 from http://www.process-improvement-institute.com/_downloads/Human_Factors_Elements_Missing_from_PSM.pdf